1, automatic temperature control energy-volume heat exchanger, which make full use of steam energy efficiency, energy saving is a new water heater. Ordinary water of heat exchanger generally needs to be configured to reduce the temperature of the steam condensate for reuse. The energy-efficient heat exchanger condensate water temperature at about 75 ℃, can be reused directly back to the boiler room. This reduces the investment in equipment, saving heat exchanger room area, thereby reducing infrastructure costs, and therefore the volume of energy-efficient heat exchanger by the majority of design, user units welcome.

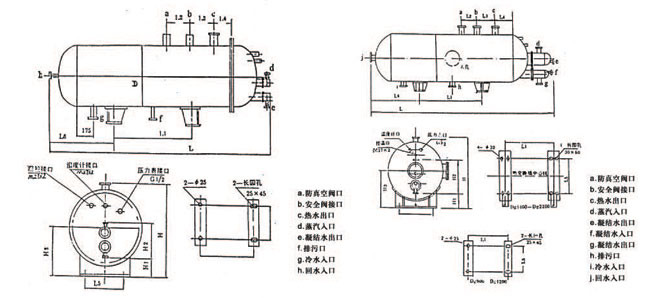

2, energy-efficient heat exchanger volume detailing works are shown. There are vertical, horizontal two types, its technical parameters detailed chart after page, complete factory production specifications, but also by the specific needs of the user units design and processing.

3, the heat exchanger is suitable for general industrial and civil construction of water supply systems. Htm for steam heating calandria working pressure, <0.6Mpa, working pressure shell 0 ~ 1.6Mpa, hot water outlet temperature is 65 ℃.

4, the volume of energy-efficient heat exchanger, there are three kinds of shell material: carbon steel Q235-A, B, stainless steel 1Cr18Ni9Ti, carbon steel lined copper, U-shaped pipe material, T2 copper and stainless steel 1Cr18Ni9Ti. May need to be chosen.

5, horizontal energy-saving for steel saddle supports. And international S154, the same as S165. Vertical for pedestal stand.

6, the heat exchanger must set safety devices, the following types of safety devices fitted to choose one on the switch:

1) In the exchanger top mounted safety valve, pressure relief valve shall be the maximum working pressure heat exchangers need to be declared fit when (ordering the safety valve manufacturing plant). Installation and use of the safety valve should follow the "pressure vessel safety regulations and technical supervision," the provisions of labor and personnel department.

2) installed at the top of the switch is turned out of the air tube (in the case of conditional)

3) Let the expansion tank connected to the water heater, for discharging the water expansion.

When 7 Flow containing hardness salts, the use of heat exchangers, the wall and the wall will be the formation of scale, resulting in lower heat transfer rate, increasing energy consumption, and thus affect the use, it should take certain measures to soften.

8 stainless steel-lined copper heat exchanger than the economy, and technically assured. It takes advantage of the strength of steel and corrosion resistance of copper, which is to ensure the heat exchanger can work under pressure, and the heat exchanger water quality is good. The thickness of the steel-lined copper is generally 1.2mm steel-lined copper heat stroke must prevent a partial vacuum in the tank, so has the anti-vacuum valve when the product is shipped. This valve unless regular maintenance is definitely not canceled. Causes a partial vacuum may be improper drainage, low water pumped from excessive heat, or bad exhaust system. Water hammer or sudden pressure drop is caused by negative reasons.

|

Switch Model

|

Capacity l

|

D

|

L

|

L1

|

L2

|

L3

|

L4

|

L5

|

L6

|

H

|

H1

|

H2

|

H3

|

a

|

b

|

|

1

|

500

|

600

|

2240

|

815

|

300

|

300

|

175

|

420

|

800

|

1368

|

558

|

560

|

913

|

50

|

50

|

|

2

|

700

|

700

|

2800

|

890

|

300

|

300

|

175

|

500

|

665

|

1108

|

134

|

700

|

604

|

50

|

50

|

|

3

|

1000

|

800

|

2848

|

960

|

300

|

300

|

175

|

590

|

750

|

1158

|

134

|

700

|

604

|

50

|

50

|

|

|

c

|

d

|

e

|

f

|

g

|

h

|

Weight

kg

|

|

|

|

|

|

|

|

|

|

1

|

80

|

40

|

40

|

40

|

80

|

50

|

620

|

|

|

|

|

|

|

|

|

|

2

|

80

|

40

|

40

|

40

|

80

|

50

|

820

|

|

|

|

|

|

|

|

|

|

3

|

80

|

40

|

40

|

40

|

80

|

50

|

900

|

|

|

|

|

|

|

|

|

|

Switch Model

|

Capacity l

|

D

|

L

|

L1

|

L2

|

L3

|

L4

|

L5

|

L6

|

H

|

H1

|

H2

|

H3

|

a

|

|

4

|

1500

|

900

|

3125

|

1085

|

250

|

250

|

150

|

660

|

825

|

1270

|

126

|

788

|

664

|

50

|

|

5

|

2000

|

1000

|

2423

|

1185

|

300

|

300

|

150

|

740

|

930

|

1362

|

168

|

788

|

706

|

50

|

|

6

|

3000

|

1200

|

3690

|

1465

|

300

|

300

|

180

|

900

|

935

|

2566

|

280

|

788

|

818

|

50

|

|

7

|

5000

|

1400

|

4132

|

1645

|

300

|

300

|

180

|

1050

|

1010

|

1760

|

330

|

820

|

900

|

50

|

|

7.5

|

6710

|

1600

|

4279

|

1755

|

300

|

300

|

180

|

1180

|

1072

|

1760

|

300

|

825

|

1000

|

50

|

|

8

|

8000

|

1800

|

4348

|

1620

|

350

|

350

|

250

|

1330

|

1162

|

2144

|

250

|

1008

|

1110

|

50

|

|

9

|

10000

|

2000

|

4490

|

1620

|

350

|

350

|

250

|

1490

|

1200

|

2344

|

278

|

1012

|

1210

|

50

|

|

10

|

15000

|

2200

|

5148

|

2200

|

350

|

350

|

250

|

1680

|

1280

|

2544

|

288

|

1017

|

1314

|

50

|

|

|

b

|

c

|

d

|

e

|

f

|

g

|

h

|

i

|

j

|

k

|

kg

|

|

|

|

|

4

|

50

|

80

|

40

|

40

|

32

|

32

|

50

|

50

|

50

|

|

1080

|

|

|

|

|

5

|

50

|

80

|

40

|

40

|

32

|

32

|

50

|

50

|

50

|

|

1450

|

|

|

|

|

6

|

50

|

100

|

50

|

50

|

40

|

40

|

50

|

50

|

50

|

|

1760

|

|

|

|

|

7

|

50

|

100

|

50

|

50

|

40

|

40

|

50

|

50

|

50

|

110

|

1930

|

|

|

|

|

7.5

|

50

|

100

|

50

|

50

|

40

|

40

|

50

|

50

|

50

|

110

|

1930

|

|

|

|

|

8

|

50

|

100

|

65

|

50

|

50

|

50

|

80

|

50

|

50

|

110

|

3800

|

|

|

|

|

9

|

50

|

125

|

80

|

50

|

50

|

50

|

80

|

50

|

50

|

110

|

6340

|

|

|

|

|

10

|

50

|

125

|

80

|

50

|

50

|

50

|

80

|

50

|

50

|

130

|

9392

|

|

|

|

1,2,3 horizontal volumetric heat total figure

4,5,6,7,8,9,10 horizontal displacement of energy-saving heat exchanger General Plan

|